Accelerometers, transducers and portable vibration meters

Every Monitran sensor is individually tested and shipped with a signed and dated test certificate. Calibration is conducted at our factory using a ‘back-to-back’ reference accelerometer excited by a precision frequency-controlled power amplifier, thus giving a traceable performance to UK National Standards. The sensitivity in mV/g for accelerometers and the 4-20mA range for velocity and acceleration transducers are confirmed and reported at 80Hz and 20ºC.

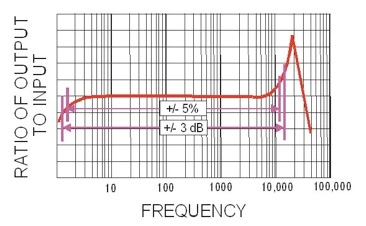

The graph below shows a typical accelerometer frequency response from which it can be seen that the calibration frequency falls well within the ‘flat response’ region of operation.

Upon request (and for a small additional fee) a multi or full-frequency response scan can be supplied.

Experience shows that providing our sensors are not misused their sensitivity will remain stable for many years. The result is that our customers can rely on trending results from our equipment long after installation with little or no maintenance. This reliability is particularly relevant where our sensors are installed in remote areas or in harsh prevailing conditions.

Some applications, for example scientific and R&D work, require sensors to be maintained in calibration. In such cases Monitran is able to offer a formal recertification service on request. Alternatively, for users who have large numbers of accelerometers to maintain and certify, our VC20 portable vibration calibrator will be an invaluable tool.

Although our sensors maintain their stability very well in arduous conditions, the performance of portable equipment can be adversely affected by everyday handling. For users of our portable vibration meters MTN/VM220, therefore, we recommend recertification on an annual basis to ensure the long term reliability of results. Please return your meter, probe and cable assembly to Monitran with a purchase order for the work and contact the sales department for current price and delivery terms.

Proximity systems

A proximity system comprises an eddy current probe, extension cable and driver – all of which are individually tested and shipped with a signed and dated test certificate.

The sensor is calibrated against a standard ANSI4140 carbon steel sample typical of the materials used in pump and turbine shafts. The probe-to-target distance is varied on a precision positioning jig while the driver electronics are tuned to ensure a non-linearity of <1% over the operating range.

Using other materials as the target in the field will lead to differences in sensitivity and linearity from this primary calibration.

However, on request calibrations can be performed against user-supplied target materials. In such cases it must be understood that the linear operating range of the probe will vary according to the target material’s permeability and resistivity.

Each system once assembled and calibrated must be considered as a single unit of which the parts are not interchangeable. While probes of the same range and extension cables of the same length and identical drivers may each be physically interchanged, the system outputs will change and recalibration will be necessary to maintain the safety of the machine which the system protects. This will necessitate the return of the whole system to Monitran unless sophisticated local calibration facilities are available.

If damage occurs to one element of a system, Monitran recommends that the whole system be replaced as soon as possible to maintain safety of the machinery. If desired and if practical, the original equipment may be returned for investigation, repair, recalibration and return as a spare to guard against future failure.

LVDT's

Each complete LVDT system is individually tested and shipped with a signed and dated test certificate. The LVDT is mounted in a precision positioning jig where the null point is determined electronically. The output is then measured at 10 points across the range and electronically adjusted to achieve the non-linearity reported on the certificate. This is normally <0.5%, but on special request can be reduced to 0.25% for some models.